Benefits of Using a Proper Air Filter in Your Setup

Pneumatic systems drive many industrial operations, from assembly lines to construction equipment, using compressed air to power cylinders, actuators, and tools with precision and force. However, the quality of compressed air directly affects performance and reliability.

Compressed air often contains contaminants that can damage equipment. Water vapor condenses as air cools, causing moisture that corrodes components. Oil from compressors and dirt from intake valves or leaks mix into the air stream, accumulating and causing damage over time. Understanding the benefits of using a proper air filter in your setup can save you money on repairs, downtime, and equipment replacement.

Understanding Pneumatic Air Filters

The air filters in pneumatic systems remove solid particles, water droplets, and oil aerosols from compressed air before it reaches sensitive components such as valves, cylinders, and control systems.

Particulate Filters

Particulate filters capture solid contaminants using various filtration media. These filters typically feature pleated elements that trap particles while allowing clean air to flow through. The filtration rating, measured in microns, determines which particle sizes the filter can effectively remove. Standard particulate filters handle particles down to five microns, while high-efficiency versions can capture contaminants as small as 0.01 microns.

Coalescing Filters

Coalescing filters specialize in removing liquid contaminants, including water and oil aerosols. These filters use special media that cause tiny liquid droplets to merge into larger drops, which then drain away through automatic or manual drain systems. The coalescing process is essential for preventing liquid contamination from reaching downstream components.

Combination Units

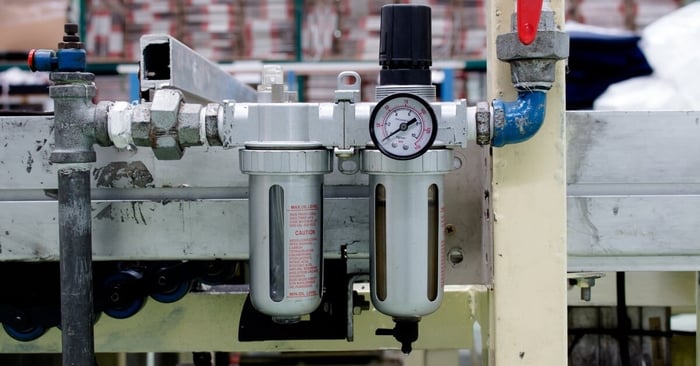

Many pneumatic systems benefit from combination filter regulator lubricator (FRL) units that integrate multiple air treatment functions. These compact assemblies provide filtration, pressure regulation, and controlled lubrication in a single package, streamlining installation and maintenance while ensuring comprehensive air treatment.

Extended Equipment Lifespan Through Proper Filtration

Contaminated compressed air accelerates wear and corrosion throughout pneumatic systems. Solid particles act as abrasives by grinding away at cylinder seals, valve seats, and other precision surfaces. Water accelerates rust and corrosion, posing significant harm to steel components and often leading to blockages in narrow passages.

Clean, filtered air dramatically extends component life by eliminating these destructive contaminants. Cylinder seals last longer when protected from abrasive particles, while valves maintain their sealing integrity without contamination buildup. Internal passages remain clear, preventing restriction and maintaining proper flow rates.

The financial impact of extended equipment life becomes apparent over time. Components that might require replacement every two years can operate effectively for five years or more with proper filtration. This extension applies to everything from small actuators to large industrial cylinders, creating substantial savings across an entire pneumatic system.

Protecting Precision Components

Modern pneumatic systems often incorporate sophisticated control valves, proportional regulators, and servo actuators that need exceptionally clean air. These precision components feature tight tolerances measured in thousandths of an inch, making them particularly vulnerable to contamination damage.

Proper air filtration ensures these sensitive components receive the clean air they need to function reliably. Without adequate filtration, microscopic particles can cause control valves to stick, regulators to drift, and actuators to lose positioning accuracy.

Enhanced System Performance and Efficiency

Clean compressed air flows more efficiently through pneumatic systems, reducing pressure drops and energy consumption. Contamination creates restrictions in air passages, forcing compressors to work harder to maintain system pressure. This increased workload leads to higher energy consumption and significantly lowers overall efficiency.

Filtered air also improves the response time of pneumatic actuators and tools. Clean air passages allow rapid pressure changes for quick cycling and precise control. Systems operating with contaminated air often exhibit sluggish response times and reduced force output due to restricted flow and pressure losses.

Consistent Performance Characteristics

Pneumatic systems with proper filtration maintain consistent performance over time. Clean air ensures that actuators develop their full rated force, valves switch reliably, and control systems respond predictably. This consistency is crucial for automated processes where variations in timing or force can affect product quality.

Without adequate filtration, system performance gradually degrades as contamination accumulates. What starts as barely noticeable changes in cycling time or force output eventually becomes significant enough to impact production quality and efficiency.

Reduced Maintenance Costs and Downtime

Maintenance costs decrease substantially when pneumatic systems operate with clean, filtered air. Components run longer between service intervals, reducing labor costs for routine maintenance. When performing service, technicians spend less time cleaning contamination and more time on productive maintenance activities.

Unplanned downtime also drops significantly with proper air filtration. Emergency repairs caused by contamination-related failures become rare events rather than regular occurrences. This is particularly valuable in continuous production environments where downtime expenses can reach thousands of dollars per hour.

Predictable Maintenance Scheduling

Clean pneumatic systems allow for predictable maintenance scheduling based on actual operating hours rather than contamination-driven failures. This predictability enables better maintenance planning, inventory management, and resource allocation. Maintenance teams can schedule work during planned downtime rather than responding to emergency situations.

The ability to predict maintenance needs also improves spare parts management. Instead of stocking emergency repair components, maintenance departments can focus on planned replacement items, reducing inventory costs while ensuring parts availability when needed.

Enhanced Workplace Safety

Contaminated pneumatic systems pose several safety risks that proper filtration helps eliminate. Water in compressed air lines can freeze in cold conditions, blocking air flow and causing unexpected equipment shutdown. Oil contamination creates slip hazards when it leaks from fittings or accumulates around equipment.

Clean, filtered air reduces these safety concerns while improving overall system reliability. Workers can depend on pneumatic tools and equipment to operate consistently, reducing the risk of accidents caused by equipment malfunction or unexpected behavior.

Preventing System Failures

Proper air filtration prevents many types of system failures that can create safety hazards. Contamination-related valve malfunctions can cause unexpected actuator movement, while clogged passages can lead to pressure buildup and potential hose or fitting failures.

By maintaining clean air throughout the system, proper filtration ensures that safety devices such as emergency stops and pressure relief valves function reliably.

Optimize Your Pneumatic Air Quality Today

The benefits of using a proper air filter in your setup include greater equipment longevity, energy efficiency, operational safety, and cost control. When compressed air systems receive the clean, dry air they need, they offer consistent performance, reduced maintenance expenses, and improved productivity.

PneumaticPlus offers comprehensive FRL units designed to optimize pneumatic system performance through high-quality air treatment. These integrated solutions provide superior filtration, precise pressure control, and adjustable lubrication to protect your investment while maximizing operational efficiency. Browse our selection to find the best FRL system for your pneumatic operations.