Walker Filtration Oxygen Filters – Coalescing & Particulate (O20006–O21500)

High Purity Filtration for Oxygen Generation Systems

Walker Filtration Oxygen Filters are engineered to deliver superior protection and performance for oxygen generation. Designed for both inlet air pre-filtration and post-generation gas treatment, these filters ensure compliance with oxygen purity standards by removing particulate, liquid aerosols, and contaminants.

Key Features

-

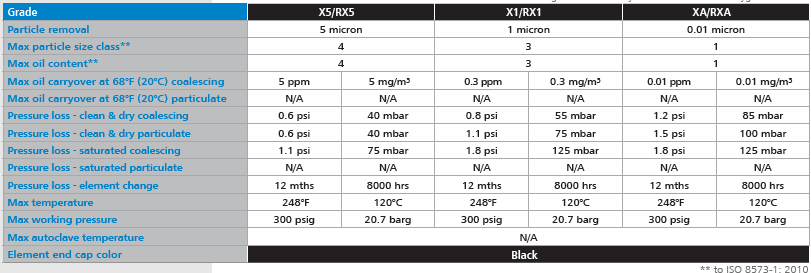

Filtration Range: 5 micron, 1 micron, and 0.01 micron (X5/RX5, X1/RX1, XA/RXA)

-

Flow Rates: From 5.7 SCFM (9.5 Nm³/hr) to 1425 SCFM (2422.5 Nm³/hr)

-

Connections: From 1/8" to 3" NPT (BSP options available on request)

-

Certified for Oxygen Service: Cleaned in accordance with ASTM G93/G93M to eliminate combustible contaminants

-

ISO 8573-1:2010 Compliant: Maximum oil carryover as low as 0.01 ppm at 0.01 micron grade

-

Durable Construction: Cast aluminum alloy housings with corrosion-resistant powder coating

-

Easy Maintenance: Push-fit elements, externally accessible drain, and modular filter head design

Applications

-

Medical Oxygen Generation

-

Food & Beverage Production

-

Steel & Metal Processing

-

Electronics Manufacturing

-

Automotive Industry

Technical Specifications

-

Working Pressure: Up to 300 psig (20.7 barg)

-

Maximum Temperature: 248°F (120°C)

-

Flow Direction: Inside-to-out for coalescing elements, outside-to-in for particulate elements

-

Service Life: Replace elements every 12 months / 8000 hours (whichever comes first)

Filter Element Specifications: