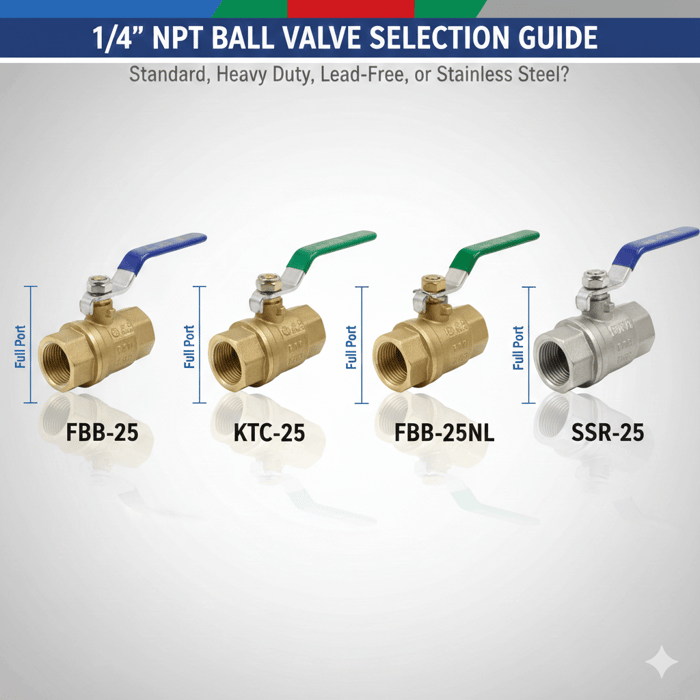

1/4" NPT Ball Valve Selection Guide: Standard, Heavy Duty, Lead-Free, or Stainless?

Selecting the right 1/4" NPT ball valve involves more than just matching thread sizes. Choosing the wrong material or pressure rating can lead to system leaks, failed inspections, or premature component failure in critical industrial environments.

At PneumaticPlus, we provide four distinct tiers of 1/4" NPT ball valves. This guide breaks down the technical differences between Standard Brass, Heavy Duty, Lead-Free, and 316 Stainless Steel to help you select the exact component for your application.

1. The Industrial Workhorse: FBB-25 (Standard Brass)

The FBB-25 is the industry-standard choice for general-purpose MRO (Maintenance, Repair, and Operations). It is engineered for reliability in standard compressed air circuits.

- Primary Applications: Air compressor tank drains (Manchester/Samuel), pneumatic tool drops, and general shut-off.

- Technical Highlight: 600 PSI WOG rating with a Full Port design for unrestricted flow.

- The Advantage: An ideal upgrade for "wing-nut" petcocks on air receiver tanks, preventing the clogs common with manual needle valves.

Shop FBB-25 Industrial Standard Valve

2. The High-Pressure Specialist: KTC-25 (Heavy Duty Brass)

When your system faces extreme vibration or requires official gas certifications, the KTC-25 is the necessary upgrade. It features a high-density body casting for superior safety margins.

- Primary Applications: Fuel gas lines, high-vibration mobile compressors (truck-mounted), and high-pressure air systems.

- Technical Highlight: Dual CGA/AGA Gas Certifications and a 900 PSI Maximum Pressure rating.

- The Advantage: Mandatory for compliance in fuel gas service where standard pneumatic valves do not meet code requirements.

Shop KTC-25 Heavy Duty Gas Valve

3. The Health & Compliance Hero: FBB-25NL (Lead-Free Brass)

For systems carrying water intended for human consumption or contact, the FBB-25NL is the certified solution. It eliminates lead leaching while maintaining industrial durability.

- Primary Applications: Potable water systems, food and beverage processing, and medical air lines.

- Technical Highlight: Certified to NSF/ANSI 61 & 372; upgraded with a Stainless Steel Ball for better corrosion resistance.

- The Advantage: Meets AB1953 (California) and Federal Safe Drinking Water Act mandates.

4. The Lifetime Upgrade: SSR-25 (316 Stainless Steel)

When brass construction is insufficient for harsh environments, the SSR-25 provides ultimate corrosion resistance. Constructed from investment-cast 316 Stainless Steel, it is built for longevity.

- Primary Applications: Chemical processing, marine environments, high-temperature steam, and automated systems.

- Technical Highlight: 1000 PSI CWP rating and an integrated ISO Mounting Pad for actuators.

- The Advantage: The 316 grade stainless steel protects against pitting and corrosion in saltwater or chemical washdown areas.

Shop SSR-25 316 Stainless Steel Valve

Ball Valve Comparison Summary

| Requirement | Valve Model | Key Benefit |

|---|---|---|

| Standard Air / MRO | FBB-25 | Reliable & Cost-Effective |

| Fuel Gas / High Pressure | KTC-25 | CGA/AGA Certified |

| Potable Water / NSF | FBB-25NL | Safe Drinking Water Compliant |

| Marine / Chemicals | SSR-25 | 316 SS Corrosion Resistance |

Authorized Distributor Verification: PneumaticPlus is an authorized distributor for the products listed on our platform. We verify the authenticity of all components sold and provide them in factory-new condition unless otherwise indicated. All products meet rigorous manufacturer specifications for industrial safety.

Technical Reference Disclaimer: While PneumaticPlus provides technical information and compatibility references as a courtesy, this data is for informational purposes only. Specifications are sourced from manufacturer data and are believed to be accurate at the time of publishing. Users must confirm all technical requirements and compatibility with the original equipment manufacturer (OEM) or a licensed professional before installation.